The Materials Engineering group, situated in the Department of Mechanical and Mechatronic Engineering at the University of Stellenbosch, is working with many of the leading national and international institutions in the area of materials engineering. The level of contact varies from fully funded research projects, through to partial funding of projects or studentships, to general collaboration and interchange of knowledge and expertise.

The group has established expertise, equipment and laboratory facilities to conduct research into materials engineering related problems. Our research focuses on developing numerical-experimental techniques to obtain an understanding of material behaviour for modelling and predictive capabilities.

Our Focus

- Develop numerical-experimental techniques to obtain material properties.

- Linking manufacturing processes to material performance.

- Develop material models for predictive capabilities.

- Material characterisation and analysis.

Our Objectives

- To establish a hub for expertise in Materials Engineering at Stellenbosch University that closely collaborates with local partnering universities to strengthen the skills level in South Africa.

- To be at the forefront of academic excellence.

- To assist South African companies through technological solutions.

- Providing consultancy services to industry.

Our Expertise

- Fracture Mechanics

- Damage Mechanics

- Material Characterisation

- Microstructural Analysis

- Digital Image Correlation

- Digital Volume Correlation

- Powder Metallurgy Processing

- Finite Element Analysis

Principal Researchers

Prof Deborah Blaine

Associate ProfessorProf Deborah Blaine is an Associate Professor in the Department of Mechanical and Mechatronics Engineering at Stellenbosch University. Her research focuses on powder materials and processing, most recently including laser powder bed fusion, and sintering of die-compacted and gel-cast materials. Her research typically evaluates the mechanical behaviour of materials with specific focus on the relationships between processing-property-performance for powder-based materials. Additionally, she is passionate about teaching and learning, and the development of professional teaching practice for academics. She currently holds a Teaching Fellowship at Stellenbosch University where she is exploring how the engineering curriculum can be redesigned to incorporate diverse inputs from students, academics, industry and support staff, in order to develop an approach to teaching and learning that is more suited to the South African context.

She joined Stellenbosch University as a senior lecturer in 2007. Prior to this she was the deputy manager of materials research and development at Bleistahl Produktions, GmbH & Co. KG in Germany. Bleistahl is the second largest global manufacturer of sintered valve seat inserts and valve guides. She holds a PhD (2004) in Engineering Science and Mechanics from the Pennsylvania State University and a BEng (1996) in Mechanical Engineering from Stellenbosch University.

Prof Thorsten Becker

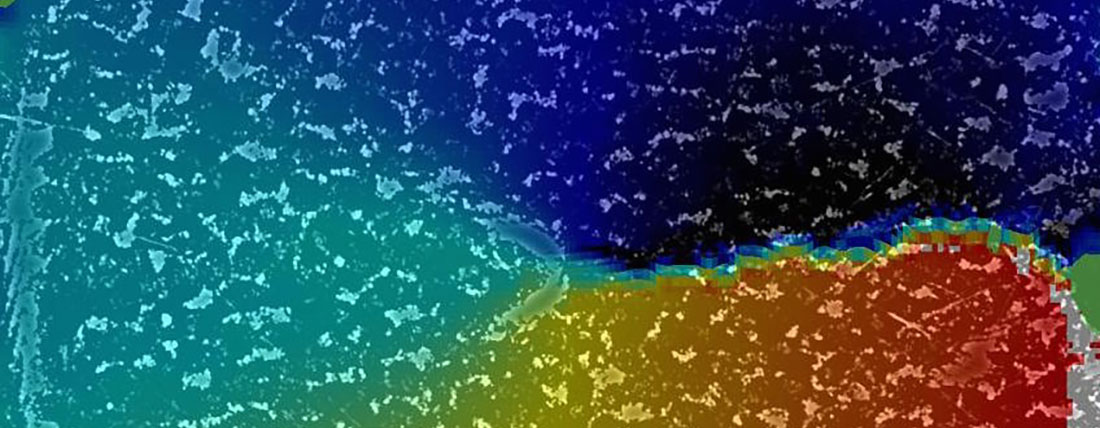

Extraordinary Associate ProfessorThorsten Becker is appointed as Associate Professor in the Department of Mechanical Engineering while holding the role of the director for the Centre of Materials Engineering at the University of Cape Town. Prof Becker is also appointed in an extraordinary position in the Mechanical and Mechatronic Engineering department at Stellenbosch University. Prof Becker’s research interest is in structural integrity: fatigue, fracture and creep. His work aims to use advanced techniques such as digital image and volume correlation, high-resolution microscopy and finite element modelling to measure and extract engineering parameters for structural integrity assessments. One of his keen interests lies in the additive manufacturing of metals and high temperature applications. His work closely collaborates with local and international institutions to develop a better understanding of the process inherent attributes and their link to the material’s structural performance. Prof Becker also acts on various professional bodies and consultants to industry, particularly in the field of Fracture Mechanics

Dr Melody Neaves

LecturerI hold the position of Lecturer in the Mechanics division of the Department of Mechanical and Mechatronic Engineering at Stellenbosch University since 2020. My PhD focused on the development of material-efficient damage assessment techniques for service-retrieved high-energy steam piping that were exposed to creep conditions in South African fossil-fuelled power stations. These include non-contact photomechanical techniques, such as Digital Image Correlation (DIC), over non-uniform material, stress and temperature fields. DIC results are compared with conventional and microstructural methods of damage assessment to give a holistic assessment of creep damage. I am currently involved with projects related to small-sample testing in collaboration with the University of Bristol, energetic materials testing and 3D printing as well as combining such methods with DIC available at Stellenbosch University.

Vinay Shekhar

Senior LecturerDr Vinay Shekhar is a new lecturer in the Department of Mechanical and Mechatronics Engineering at Stellenbosch University. He holds a BSc(Eng), MSc, and PhD from the University of Cape Town (UCT). In his PhD, he investigated the response of GFRP and steel V-structures to localised air-blast loads. The study involved the manufacture of GFRP V-structures using vacuum infusion (VI) and the use of high-speed cameras and digital image correlation (DIC) to film and investigate the transient response of these V-structures during the blast loading events. His lecturing background includes teaching Mechanical Vibrations, Engineering Dynamics, and Solid Mechanics at UCT. He is currently involved in lecturing Strength of Materials and Machine Design. His research interests include material testing and characterisation, and numerical modelling and optimisation of structures subjected to impact and blast loads.

Dr Nur Dhansay

LecturerDr Nur Mohamed Dhansay is a new lecturer in the Department of Mechanical and Mechatronics Engineering at Stellenbosch University. He completed his PhD in 2021 at Stellenbosch University under the supervision of Professor Thorsten Becker and Professor Kim Vanmeensel (KUL). His research focussed on the near-threshold fatigue crack growth rates of laser powder bed fusion produced Ti-6Al-4V. Nur spent a substantial portion of his PhD in Belgium at KU Leuven where he conducted majority of his experiments. Nur was successful in obtaining a job at Stellenbosch University and is now lecturing a second year and third year Strength of Material course and looks to further his research in fracture mechanics and failure analysis topics.

Dr Gerrit Ter Haar

Postdoctoral researcherAfter completing his mechanical engineering bachelor’s degree at Stellenbosch University in 2014, Dr Ter Haar started his master’s degree on the topic of additive manufacturing of titanium alloys the following year. Having completed his master’s degree cum laude, Dr Ter Haar pursued a PhD in the same field which he completed in 2020. Dr Ter Haar was then appointed as a post-doctoral research assistant at Stellenbosch University during 2021 in which he broadened his research scope to include novel beta-titanium alloys. Dr Ter Haar currently holds the position of lecturer at the engineering faculty of Stellenbosch University.

Raymond Botete

Junior LecturerBorn and raised in Limpopo where I completed my matric. I came to Stellenbosch in 2012 to start my undergrad in Mechanical Engineering and graduated 2016. I immediately continued with master’s degree under the supervision of Prof Gerhard Venter working on the prediction of fibre waviness defect during the curing process of thermosetting composite panel with ply drop-offs. I am currently appointed as the Junior Lecture in the Mechanical and Mechatronic engineering department. I will also be doing research for PhD studies on the prediction of microstructure and composition in laser-based additive manufacturing of titanium alloys.

Llewellyn Cupido

Junior LecturerHailing from a country such as a Namibia, one’s natural affinity is towards heat and toughness. My interest is in understanding the effects of temperature on the properties of metals, the improvement through heat treatment, and modelling and process optimisation. With a MEng in Foundry Technology from AGH University of Science and Technology, and a MTech in Mechanical Engineering from Cape Peninsula University of Technology, I got appointed as a research engineer at the Engineering department at CPUT to establishing a technical research unit. I got involved with the local foundry industry and assisting students in linking metallurgy to mechanical engineering. This exposure contributed to my knowledge gained in aluminium, titanium and iron alloys. Currently appointed as a Junior Lecture in the Mechanical and Mechatronic engineering department, I will also continue my PhD studies on the modelling of precipitation strengthening in steels.

Postgraduate Researchers

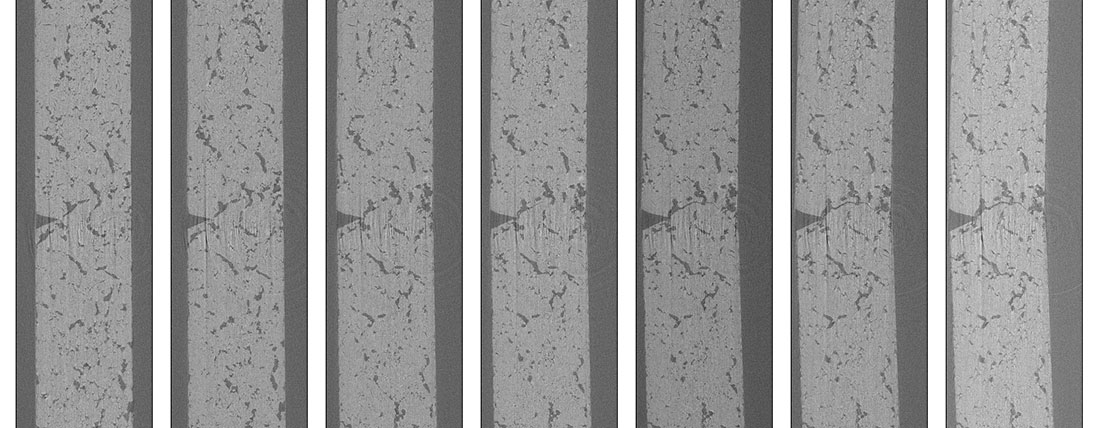

Danie Louw

PhDI obtained a Bsc in Physics and Mathematics from North-West University in 2011 after which I completed a Bsc(Hons) in Materials Science at University of Cape Town in 2012. In 2013 I was fortunate enough to be offered a Masters Studentship at the CSIR(Council for Scientific and Industrial Research). During my Studentship I completed a Msc(Applied Science) in Metallurgy at University of Pretoria where I looked at developing process parameters for the novel and ambitious Aeroswift project that was run by CSIR and Aerosud. After finishing my Msc I was fully employed by CSIR in 2015 where I still work. I started my PhD at University of Stellenbosch in the Materials Engineering research group under supervision of Prof TH Becker in 2019. For my PhD I am looking at ways to predict and prevent support failure and delamination that can occur during Laser Powder Bed Fusion of metals.

Preyin Govender

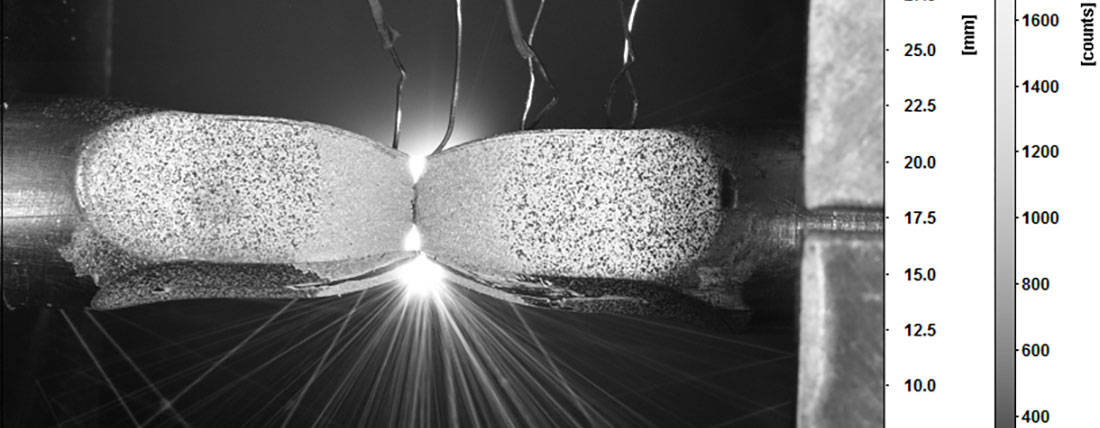

PhDI was born In Johannesburg, Lenasia where after years of travelling around South Africa I settled in Mthatha in the Eastern Cape. I went to school in East London at Selborne College where I matriculated in 2013. I completed my undergraduate degree in Mechanical Engineering at Stellenbosch University by 2017. I then enrolled for postgraduate studies for the year 2018 under the supervision of Prof DC Blaine of which I have completed in 2020. I am currently enrolled as a PhD student in the Materials department with my project focused at Process development of WC-Co for Selective Laser Melting (SLM). The effects of various parameters and powder morphology on printed SLM components shall be investigated and reported.

Labau Cremer

PhDI was born in Pretoria and matriculated in 2016 from Afrikaanse Hoër Seunskool. I started my studies in 2017 at the University of Pretoria towards Mechanical Engineering and graduated with Cum Laude in 2020. In 2021, I enrolled for my master’s degree in Mechanical Engineering at Stellenbosch University under the supervision of Dr J van der Merwe and Prof T Becker. My research focuses on determining the feasibility of additively manufacturing, patient-specific metallic articulating implant components. The research is mainly focussed on obtaining tribology experimental data by using a pin-on-flat wear testing machine.