SU vibration scientists help make sense of mechanical shudders on polar vessel

Jorisna Bonthuys

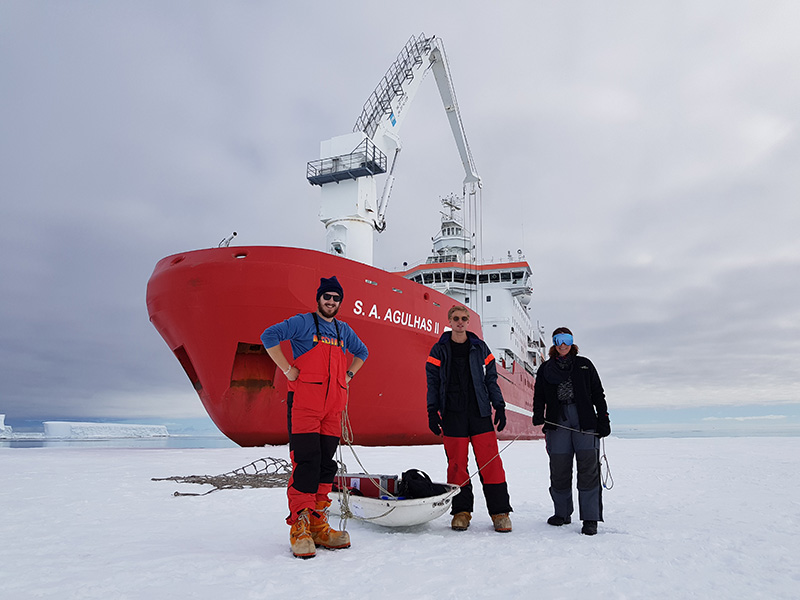

Prof Annie Bekker on the deck of the SA Agulhas II during the Endurance22 expedition. | Photo by James-John Matthee

Prof Anriëtte (Annie) Bekker, a vibration science expert at Stellenbosch University (SU), is willing to brave harsh conditions in pursuit of new knowledge.

Her interest lies in how data from mechanical sensors and engineering models on board a polar vessel can help seafarers make more informed decisions towards safer ship operations.

Bekker is fascinated, for instance, by what engineers could learn from the way a vessel shudders in the icy Southern Ocean during a wreck hunt. More specifically, she marvels at the sound on such a vessel and gets excited about the research opportunities they offer.

Bekker holds the Gibela Engineering Research Chair in SU’s Department of Mechanical and Mechatronic Engineering. After joining the department in 2011, she became its first female professor in 2020, and today also heads up its Sound and Vibration Research Group (SVRG).

Over the last decade, Bekker and members of the SVRG have investigated noise and vibration in the shipping and engineering industry. Their work now includes rotor and structural dynamics, and a role in the operational deployment of digital twin technology. (Put simply, a digital twin is a virtual replica of a physical object, process, or person that can be used to simulate their behaviour to support decisions through information.)

Prof Annie Bekker (right), with students Christof van Zijl (middle) and the late James-John Matthee (left) during ice fieldwork on the 2019 Weddell Sea Expedition. | Photo by Harry Luyt

High waves hit the bow of the SA Agulhas II | Photo by Karl Pferdekamper

SA Agulhas II docked in sea ice, while scientists are searching for the wreck of the Endurance. | Photo by Prof Annie Bekker

SA Agulhas II leaves Cape Town harbour for the Weddell Sea in the Antarctic. | Photo by Prof Annie Bekker

Wired for sound

Bekker discovered her passion for the vibration of structures as a third-year student in mechanical engineering. At the time, she was a student in Prof Wikus van Niekerk’s vibration and noise class. Now the dean of the faculty, Van Niekerk fuelled her interest in vibration science. But her fascination with sound started much earlier, as a young girl growing up in Benoni.

Her parents, a mechanical engineer and a doctor, are passionate about engines and classical music, and instilled a similar interest in sound in Bekker and her two brothers. “In the mornings, my father drove us to school in what can be described as a daily vehicle performance test, which sparked my interest in the topic. In the evenings, I practised playing my violin with my mother, who plays the piano.

“Music, like engineering, is a science of precision; it has rules,” she says. “But the sequence of notes can change in character in the skilled hands of a musician. Mechanical forces — be it the pressure of fingers on piano keys, or waves crashing onto a ship’s hull — give rise to vibrations, some of which are transmitted to the air and experienced as sound. I am curious about the nuances that give sound a special quality and the science that allows us to pinpoint these qualities.”

For Bekker, the versatile field of engineering has served as a springboard for her diverse research into topics such as dynamic seat comfort in automobiles (for Ford Motor Company) and the prediction of bone fractures in occupants of vehicles caught in landmine blasts (for Armscor).

She also worked on the noise and psychoacoustic responses that ‘compose’ a positive driving experience for buyers in the emerging electrical car market during Optimal Energy’s development of the Joule vehicle, South Africa’s first electric car. “I spent a lot of time sticking sensors on vehicles and listening to their sounds in the office,” Bekker says. Although the Joule was never commercialised, the project rewarded her with valuable experience, propelling her career into new directions.

She has led multi-sensor measurement campaigns on the heavy mobile equipment fleet for Richards Bay Minerals, as well as on polar vessels. Her work now centres around the vibration of machinery and structures.

Master’s student James-John Mathee, checking instrumentation on the SA Agulhas II portside propulsion shaft. | Photo by Prof Annie Bekker

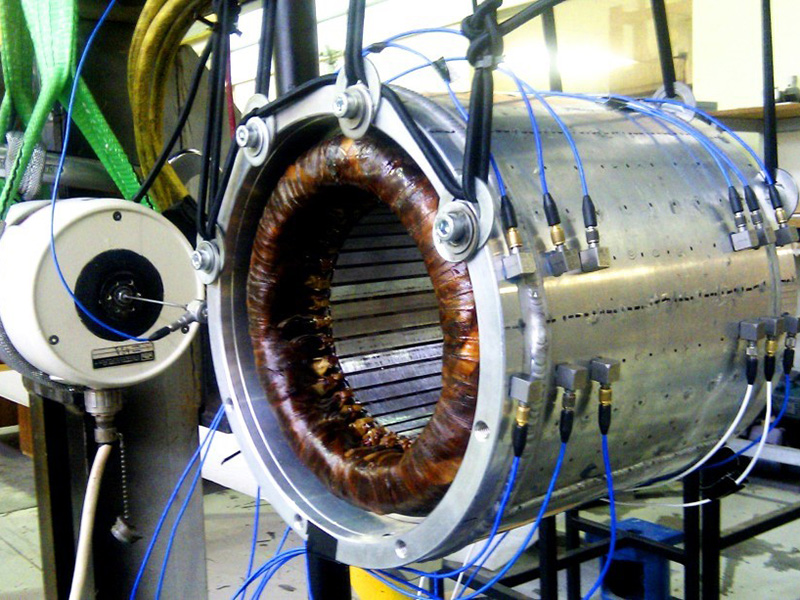

A shaker excites the structural responses of a prototype electric motor stator (and housing) for an experimental modal analysis test. Such a test determines the problematic speeds where the motor will whine if it is installed in an electric car. | Photo by Andrew Wade

Research aboard a polar vessel

Over the last decade, Bekker and 34 of her students and collaborators have benefited from exposure to scientific work on the aforementioned SA Agulhas II — Africa’s only polar supply and research vessel, which offers unique research opportunities for scientists. Built in Finland, this vessel is one of the world’s largest and most modern research ships, able to break through metre-thick ice while making her way at five knots.

In particular, Bekker and her students have focused on how the vibration of this vessel, caused by ice and waves, impacts its hull structure and propulsion system, as well as the humans on board.

Doing research on a working polar vessel of this kind requires researchers to go the extra mile, Bekker says. “Such effort is totally worth it, though, given the opportunity to do cutting-edge research. I believe this project fosters grit in our graduates, which makes them offer something unique to the workplace.”

Antarctica is the coldest, driest, and windiest place on the planet. Recent studies focused on this continent and the Southern Ocean have provided crucial insights into our changing world.

The polar regions are experiencing significant shifts, with ice loss and rapid ocean changes being observed. The west coast of the Antarctic Peninsula has, for instance, been warming at an alarming rate over the past 50 years. This warming trend is not limited to the land but can also be observed in the Southern Ocean.

Upper ocean temperatures to the west of the Antarctic Peninsula have increased by more than 1°C over the last five decades. In addition, air temperature increased by 3 °C in the Antarctic Peninsula, which is five times the mean rate of global warming. It is also worth noting that the Antarctic Circumpolar Current, which encircles the ‘White Continent’, is warming faster than the rest of the ocean. Scientists are studying this current to find out how changes to it might affect the future of Antarctica’s ice sheets and the world’s sea levels.

These and other ecological changes in the region have widespread impacts on the rest of the globe, affecting nature and humans in various ways.

Polar supply and research vessels, such as the SA Agulhas II, are vital platforms through which researchers investigate the physical and biological marine environment. “For ship responses to make sense, we have observed and recorded [qualities of] the waves and ice in the ship environment. Our data adds insight that can inform decisions regarding the efficiency and safety of ship operations and adds to our knowledge about the ability of scientists to work productively on board,” Bekker says.

The Falklands Maritime Heritage Trust enabled four engineers from SU and Aalto University (Finland) to monitor the vessel’s performance throughout the Endurance22 expedition. Here, Ben Steyn measures acoustic emissions from the ship’s propulsion shaft bearing. | Photo by Prof Annie Bekker

Digital transformation

Over the past decade, the SA Agulhas II has been equipped with an "engineering nervous system" of sensors in order to create a digital version of the vessel in operation that can serve as a prototype for Vessel 4.0.

This project, which entails taking engineering measurements on a polar ship in operation, kicked off in 2012. “In collaboration with Aalto University in Finland, we have managed to maintain the measurement effort, thereby collecting the world’s largest open data record of polar ship operations,” Bekker says.

The then newly commissioned SA Agulhas II was initially tested during ice trials in the northern Baltic Sea. This was when Bekker first became involved in doing research on this particular vessel. At the time, she was five months pregnant with her eldest son. “It was my first time on board a vessel of this kind,” she recalls. “I remember carrying all my [monitoring] equipment in a small suitcase as hand luggage on my way to Finland.”

Scientists adjust the rigging of an electromagnetic device used to estimate ice thickness along the starboard flank of the SA Agulhas II. | Photo by Prof Annie Bekker

Today, the SA Agulhas II has more than 200 engineering and monitoring sensors to measure the impact of ice and waves on the vessel, the bending and twisting of her hull, and human responses to mechanical vibrations on board.

Bekker says these sensors help pinpoint impacts and shudders as the vessel interacts with her ever-changing environment. “The sensors provide almost real-time ship data relating to vessel responses, the experiences of people on board, and the ice and waves surrounding the ship.”

The digital transformation of the hull also supports improved decision-making by both its captain and its owner — the Department of Forestry, Fisheries, and the Environment.

“This research positions our group to collaborate internationally and to explore the practicalities of Vessel 4.0 by developing a digital vessel,” Bekker says. Funding from the South African National Antarctic Programme has been pivotal in the group's efforts.

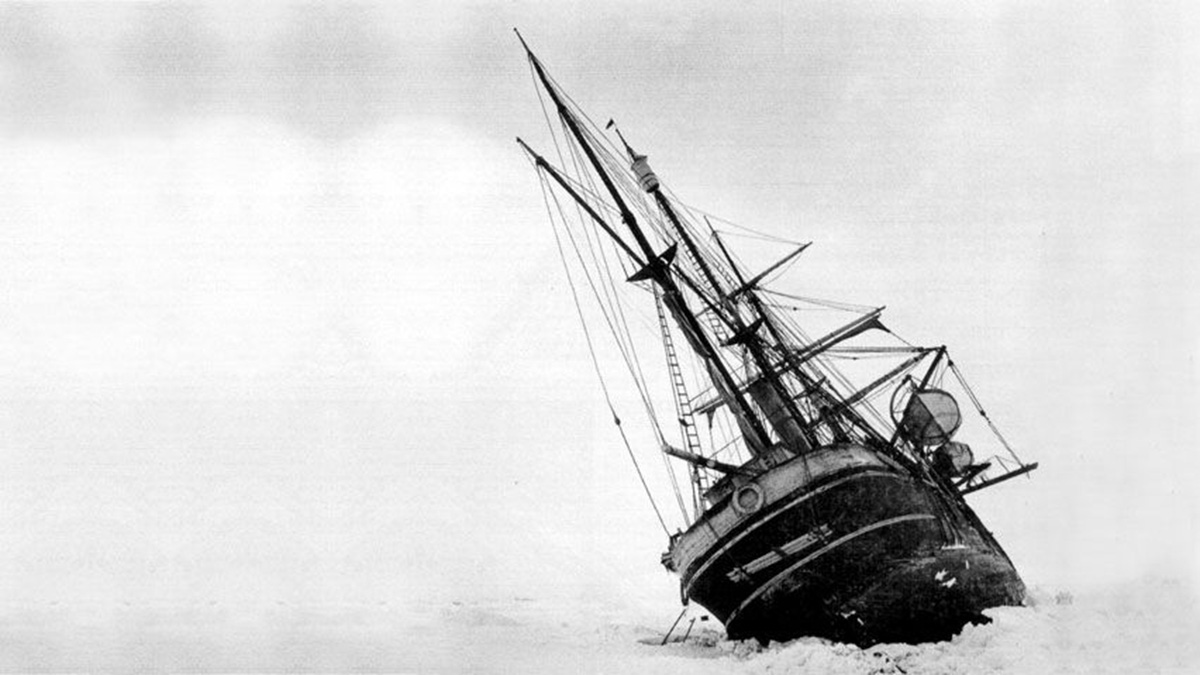

The Endurance three-masted ship of Sir Ernest Shackleton's 1914-1915 expedition trapped in pack ice. | Photo by Frank Hurley/Scott Polar Research Institute, University of Cambridge/Getty Images)

In search of a famous wreck

SU’s involvement in the digital transformation of the SA Agulhas II enabled Bekker and a team of researchers to participate in expeditions in search of Sir Ernest Shackleton’s famous shipwreck, the Endurance, in 2019 and 2022. The crew and researchers on board the SA Agulhas II aimed to navigate their way to the exact location in which the ship sank during Shackleton’s Imperial Trans-Antarctic Expedition, which took place in 1914 to 1915.

In 2022, the South African vessel embarked on the Endurance22 Expedition to the Weddell Sea. This was her second attempt to find the missing wreck of the Endurance, which — after being stuck in ice for months — was finally crushed by its sheer force in 1915. The search for her remains has been described as the world’s most difficult shipwreck hunt, with those on board battling constantly shifting sea ice conditions, blizzards, and temperatures as low as -18 °C.

During the expedition, the area that they scoured for the wreck had the lowest level of Antarctic sea ice recorded during the era of satellite monitoring, which stretches back to the 1970s. (Usually, the Weddell Sea is almost permanently covered in a thick blanket of multi-year sea ice.)

Apart from mapping the sea ice from space, representatives from the South African Weather Service, Drift+Noise, the Alfred Wegener Institute, the German Aerospace Center, Aalto University, and SU researched the ice floes, sea ice thickness, and weather conditions during the expedition. Experts from the institutions involved spent hundreds of hours conducting climate change and vessel-related studies.

Bekker, the late James-John Matthee, and Ben Steyn provided insight as to the impact of the encountered environmental conditions on the ship hull and propulsion system.

“While the vessel navigated through sea ice, we investigated propeller vibration and how the vessel handled the ocean crossing,” Bekker says. They monitored vessel performance throughout the expedition. “We measured acoustic emissions on the bearings,” she says. “This work was done with collaborating researchers at RWTH Aachen University.”

In March 2022, after more than a century, the almost pristine wooden wreck of the Endurance was located on the ocean floor at a depth of 3 000 metres.

The stern of the Endurance with the name and emblematic polestar. | Image courtesy of the Falklands Marine Heritage Trust/National Geographic

The Endurance was found deep below the Weddell Sea, where it had been preserved in remarkably good condition thanks to the cold temperatures and darkness. | Image courtesy of the Falklands Marine Heritage Trust/National Geographic

Going with the (ice) floe

During the expedition, the vessel had to navigate ice floes (thick, pancake-like ice structures), a crucial step in ensuring a polar ship’s safe voyage.

“In ice, a ship’s propeller blades interact with ice debris when it gets pushed under the hull and stern area,” Bekker explains. “Milling or single impacts of ice on the propeller cause twisting loads on the propeller which are transferred onto the propulsion shaft as vibration.”

Working in these conditions puts extreme pressure on any vessel, even the SA Agulhas II, which was designed and built for seafaring in harsh conditions, she says. “Ice impacts on the propeller can be felt throughout the ship, sometimes raising monitoring alarms.”

The SA Agulhas II reached the ice edge in the Weddell Sea during the ice minimum to kick off the search for the Endurance wreck in February 2022. The Weddell Sea marks the northernmost part of mainland Antarctica. | Photo by James-John Matthee

“Given that the ship’s propulsion shaft is about thirty metres long, we cannot place sensors where this [vibration] happens. That would be like putting rocks into your electric egg beater — the sensors simply wouldn’t survive. Rather, we place sensors safely inboard on the shaft, and use mathematics to calculate what happens 25 metres away, where the action happens at the propeller.”

Several research outputs followed from the expedition. For instance, a new model for the inverse estimation of ice-induced propeller moments (i.e. twisting loads on the propeller) on ice-going vessels has been developed based on modal superposition. In a 2022 paper on this topic, PhD candidate Brendon Nickerson outlined the loads experienced by the propellers of ice-going vessels.

Slamming is rather unpredictable on ships and can affect some of the oceanographic instruments being deployed. | Footage courtesy of Prof Annie Bekker

A whipping problem

Although the SA Agulhas II was designed with ice considerations in mind, the vessel spends most of her working days in open water. Her spoon-shaped hull enables her movement in both sea ice and open water, Bekker explains. This hybrid design also means the vessel is predisposed to wave slamming.

“On the SA Agulhas II, we noticed a problem with this slamming at the stern [of the ship], and with water rushing onto the additional deck space used for mounting container vessels. This has caused safety concerns and complaints among crew and researchers.”

Slamming is rather unpredictable on ships and can affect some of the oceanographic instruments being deployed. “When you expose ships to slamming, it creates a jelly-like motion and fatigue to the [vessel] structure, called ‘whipping’.”

Bekker believes the engineering sensors that have been installed on board can help provide valuable data on this phenomenon. The vessel’s entire hull has been equipped with sensors that measure acceleration, which is an indication of wave force. “The shape of the vessel’s hull now offers researchers the opportunity to observe whipping incidents closely, which is impossible on most other ships.”

Damage caused by whipping increases when a vessel navigates in storms. “Our research shows that if the ship is stationary with waves approaching from behind, up to 98% of the fatigue damage to the hull structure of the SA Agulhas II is caused by whipping. We noticed cracks on parts of the ship that require constant repairs. These findings are relevant to ice-going hull designs with mission profiles that cross stormy oceans, such as research and tourist ships that operate in Antarctica,” Bekker says.

The SA Agulhas II has served as a case study of the International Ships and Offshore Structures Congress subcommittee on structural longevity, which aimed to review novel developments in and challenges for predicting and monitoring vessel fatigue. As a result, Bekker has become a member of this subcommittee, which consists of experts from 15 countries.

Learning from digital twins

Technological advances have given rise to the possibility of advanced condition monitoring of a vessel through a "digital twin", which involves feeding operational data into an engineering model.

The twin is constantly updated with real-time data from sensor feeds on the ship structure and machinery, and with data about her environment, which means that the state and behaviour of the physical counterpart can be accurately reflected.

This means that previously unknown information about the ship in her ice-going environment can now be inferred by using a combination of sensor feeds and engineering models.

Bekker says the digital revolution is creating new possibilities for condition monitoring on ships. Researchers in her group have been using digital twins to remotely measure the impacts of waves and ice conditions on the SA Agulhas II, as well as the well-being of humans on board. “Over the past decade, we have performed full-scale measurements on this vessel," Bekker says. "Together with our collaborators at Aalto University [in Finland], we have created the world’s most comprehensive open source data set on polar vessel operations, based on long-term operational measurements.”

According to Bekker, their results show that the vessel operated “close to her safety margins” at times during the Endurance22 Expedition. She says their research can assist navigators with situational awareness based on the ship’s structural margins, calculated using measurements and algorithms. “Moreover, we realised that we could save unnecessary computational costs by activating monitoring algorithms only when the ship operates in ice,” Bekker says.

The SVRG is also involved in the HealthProp project, which is aimed at developing systems that can monitor the performance of a vessel under ice impact, and predict its lifespan. Funded by the MarTERA cofund scheme under the European Union’s Horizon 2020 programme, in collaboration with the South African Department of Science and Innovation, HealthProp focuses on improving the reliability and operational safety of the propulsion systems of ships.

Bekker says there is a clear need for full-scale measurements of ice impacts on ship propellers. “Although there are several tools available that provide information on ice conditions, navigators still need help quantifying actual ship operations’ structural safety margins,” she explains.

For the purposes of this project, SU researchers are partnering with the Norwegian University of Science and Technology, Hamburg University of Technology, RWTH Aachen University, Otto Piening GmbH, and EDRMedeso.

“One challenge is that local ice conditions may differ significantly from that detected by remote sensing. A digital twin or other monitoring method needs to account for these changes by evaluating whether the system was exposed to ice interaction.”

The resulting uncertainty during the design of ice-going ship propulsion systems is compensated for by over-design in an attempt to err on the side of safety.

“Even today, with our long history of seafaring, it is relevant to study ship propulsion,” Bekker says. “Propulsion failure is disastrous. The ultimate goal is to construct even better ice-breaking ships and to understand their performance in order to develop future routing systems.”

A concept depiction of digital twin services for SA Agulhas II | Image developed by Steve Macbeth for the SVRG

Mariner 4.0 simulates reality

Researchers in the SVRG are also exploring a human digital twin solution – a virtual representation of the real-time state and behaviour of a unique individual – for seafarers on the SA Agulhas II.

PhD student Nicole Taylor has introduced Mariner 4.0, a seafaring "passenger" or "crew member" with technologically augmented skills. This work explores human-related challenges on seafaring vessels and the expected value of human digital twin solutions for the maritime industry.

Bekker says Mariner 4.0 aims to represent human factors in digital systems and bridge the cyber-physical interfaces likely encountered by a seafarer in a digitalised ship environment.

Taylor’s research on this human digital twin facilitates the monitoring of motion sickness in passengers. Bekker says this information can be fused with subjective responses submitted through an Android handset and displayed on a screen.

In a recent paper, PhD student Martinique Engelbrecht proposed a threshold for the onset of discomfort induced by vibrations transmitted to the human body through wave slamming. This threshold constituted the point at which 50% of the respondents indicated a level of discomfort that disturbed their sleep and work.

Bekker says this work could contribute to comfort thresholds for cruise ships where a positive passenger experience directly affects business success.

Sound passenger transit

Bekker and a team of collaborators are now setting up a passenger train digital twin for the Gibela Rail Transport Consortium. The consortium is manufacturing 600 trains for the Passenger Rail Agency of South Africa. These trains are being built by Gibela at their bespoke plant in Dunnottar, Gauteng, in order to roll out state-of-the-art X’trapolis Mega commuter trains locally.

To help ensure that the fleet is managed optimally during its lifetime, Bekker will be applying what she learnt about digital twins on the SA Agulhas II to this new project.

She is developing a digital "watchman" in the form of a sensor array on the track that can automate some inspection tasks on trains. The project includes research on new sensors and measurement strategies, signal processing, and data fusion.

Bekker considers this work “an exciting opportunity” to help reimagine passenger train monitoring and management. “As a team, the SVRG aims to explore new data horizons and their applications,” she adds.

Bekker emphasises the role of teamwork, arguing that the greatest challenge with digital twins is the vast variety of expertise that is needed. “Any one person will have limited understanding. Luckily, I have support from colleagues throughout the Faculty of Engineering and especially in my home Department of Mechanical and Mechatronic Engineering,” she concludes.

The research initiatives reported on above are geared towards addressing the United Nations’ Sustainable Development Goals numbers 9, 13 and 14, and goal numbers 2, 6 and 7 of the African Union’s Agenda 2063

Useful links

Department of Mechanical and Mechatronic Engineering

SU's Sound and Vibration Research Group

Rediscovering the lost Endurance

South African National Antarctic Programme

Prof Annie Bekker’s inaugural lecture

Twitter: @MatiesResearch and @StellenboschUni