The added dimensions of biofuels research

Engela Duvenage

Stellenbosch University currently hosts 50 research chairs, 20 of which form part of the South African Research Chairs Initiative (SARChI), funded by the Department of Science and Innovation (DSI), through the National Research Foundation (NRF).

At the turn of the millennium, microbiologist Prof Emile van Zyl took up the challenge of driving postgraduate research and training in biofuels and other clean fuel options at Stellenbosch University (SU). His aim? To gather expertise, drive research outputs, and develop human capital to help build the necessary technology for boosting the biofuels industry in South Africa and beyond.

Van Zyl knew sustainable alternatives to fossil fuels were needed to save the world from increased climate change and pollution. “It could no longer be business as usual,” he firmly believed.

At the time, however, fears around food security caused a significant move away from the proven first-generation technologies used worldwide to convert cornstarch into biofuels.

This made Van Zyl intent on playing a part in the development of second-generation technologies and appropriate processes for producing biofuels from non-edible sources rich in starch and lignocellulose, for example sugar bagasse, invasive plants, fruit pulp, and paper mulch.

Using such low-cost waste sources readily available in South Africa held the added benefit of reducing the increased volumes of waste generated by the agricultural and forestry sectors.

Researchers are developing new technologies and processes for producing biofuels from non-edible sources.

Gathering a team

In 2007, Van Zyl was awarded the SANERI Chair of Energy Research, funded by the South African National Energy Research Institute (SANERI), now the South African National Energy Development Institute (SANEDI).

He gathered the expertise of four core members across two universities: fellow SU microbiologist Prof Marinda Viljoen‐Bloom as programme manager, Prof Hansie Knoetze and Prof Johann Görgens of SU’s Department of Chemical Engineering, and Prof Harro von Blottnitz of the Department of Chemical Engineering at the University of Cape Town.

Expertise from different fields was deliberately combined to ensure that research findings could be put into practice. The plan was that the microbiologists would do lab-based benchwork, and the engineers would tailor the processes needed to set up demonstration plants that could show the feasibility of concepts.

Between 2011 and 2022, the Senior Chair of Energy Research (CoER): Biofuels and Other Alternative Clean Fuels was funded by the then Department of Science and Technology (now the Department of Science and Innovation). Van Zyl, Viljoen-Bloom, and Görgens were appointed to steer its research. Additional funds were secured from local and international sources until the end of the Chair’s lifecycle in 2022.

The Chair set itself four major goals: to develop second‐generation technologies for biofuel production through the microbial hydrolysis (i.e., enzymatic breakdown) and fermentation of different substrates; to test methods of pretreatment, hydrolysis, and fermentation aimed at producing biofuels from lignocellulosic feedstocks; to develop better pyrolysis and gasification technologies and equipment; and to use process modelling to develop biorefinery concepts.

Research results

Over 15 years, much work was done to identify the best yeast strains and enzymes to directly ferment raw starch and lignocellulose to produce biofuels such as ethanol, high-value chemicals, bio-oil, and biogas. Biochemical and thermo‐chemical methods were evaluated, along with different yeast strains.

The Chair addressed knowledge gaps by developing improved processing and yeast technologies, considering their adaptation to local feedstocks, and assessing the economic and environmental benefits of their local implementation.

This research led to 16 patents and 286 accredited papers or book chapters.

The patents deal with different aspects of plant biomass conversion, such as different recombinant yeast strains and methods to produce and apply various enzymes to plant material to break it down to sugars that can be fermented into ethanol. Microbial enzymes can attack different kinds of polysaccharides (sugar chains), with different enzymes targeting lignocellulose, hemicellulose, and starch. Depending on the complexity of the substrate, a mixture of enzymes may be required for its complete breakdown.

The more recent patents (filed in 2021) describe the use of recombinant Saccharomyces cerevisiae (brewer’s or baker’s yeast) strains that produce enzymes for breaking down bioplastic polymers such as polylactic acid.

The role of enzymes in bioprocessing

Commercial enzymes are typically added to cellulose, hemicellulose, or starch sources to hydrolyse (i.e., convert) them into monosaccharides (“simple sugars”). Under fermentation conditions, the addition of appropriate yeast strains then kick-starts the production of ethanol by these sugars.

These two steps can be merged into one by using a consolidated bioprocessing process (CBP) which employs a single microorganism to produce the necessary enzymes to hydrolyse the base and ferment the resultant sugars.

S. cerevisiae strains that perform particularly well during fermentation have been genetically engineered to produce the required enzymes.

To construct appropriate CBP yeasts, modern genetic engineering techniques are used to introduce the cellulolytic or amylolytic traits naturally lacking in S. cerevisiae into selected strains. This significantly reduces the costs of adding commercial enzymes.

Over the years, researchers of the Chair have developed various strains of S. cerevisiae that grow well on different types of cellulose, xylan, mannan, and starch. Genes or parts of genes were inserted into S. cerevisiae host strains. Thanks to host cell engineering and adaptive evolution, new strains are now available that improve enzyme secretion and provide greater resistance to byproducts that could inhibit the breakdown and fermentation process and compound the already challenging conditions associated with industrial fermentations.

Determined growth, despite slow uptake

Despite great interest in the early 2000s, the commercial rollout of built-for-purpose second-generation biofuel plants has still not happened — not in South Africa, nor in the rest of the world, says Van Zyl.

Investors have shied away from the idea because of the significant capital input costs needed for setting up prototype plants. High energy bills and the volumes of (also very costly) enzymes needed for the conversion process have forced most companies that passed the initial planning phases into liquidation. Worldwide, only two second-generation experimental prototype plants, both in Sweden, are still in operation.

The struggles of the second-generation biofuel industry elsewhere in the world impacted South Africa’s hopes for such ventures. Not much has come from the promises of high-level government backing and investor funding that made biofuel research an attractive option in the early 2000s. By 2023, legislation signalling full support was still not signed off, despite it being drafted in the mid-2000s. Enthusiasm in certain local circles was also curtailed due to fears that biofuel production could ultimately influence food security.

Despite these high-level challenges, the members and students of the Chair continued with research steadfastly during its three life cycles, albeit with slight changes to their research focus, the feedstock sources investigated, and the end products that were targeted.

New research projects concerned with the recycling of bioplastics and the use of rumen as an inoculant to convert agricultural waste into high-end organic fatty acids are in an advanced stage.

In 2023, Görgens led the establishment of a demonstration plant at a papermill in KwaZulu-Natal where biofuels technology is used to convert paper sludge into high-value products.

“These projects would not have been possible in isolation, but resulted from cooperation within a well-equipped group with enough relevant know-how,” notes Van Zyl, now an emeritus professor at SU after retiring in 2022.

Shaping lives

Over and above their research milestones, the core members of the Chair are most proud of the young students’ lives and minds they helped shape. A total of 33 honours, 92 master’s, 39 doctoral, and 27 postdoctoral graduates benefited from the Chair either directly (via bursaries) or indirectly (by having their project running costs covered). Bursaries were awarded to 15 honours, 29 master’s, and 9 doctoral candidates, whilst 19 postdoctoral fellows or researchers were partially funded by the Chair.

“We knew that we had to deliver graduates with a strong background in various disciplines if we wanted to successfully serve the needs of a biofuel industry in both the short and long term,” says Van Zyl. “We encouraged students with potential to pursue further postgraduate studies where possible. Students from the departments of both Microbiology and Chemical Engineering attended joint meetings, journal clubs, and workshops to foster stronger interdisciplinary cooperation, the exchange of knowledge, and the development of technical skills.”

“Most of our graduates have found employment at research or academic institutions or in industry, and have been retained in the fields of science, engineering or technology,” says Viljoen-Bloom, who is continuing with yeast and enzyme research in SU’s Department of Microbiology.

“Several of our former PhD students and postdoctoral researchers have careers in industry and academia, also internationally. This demonstrates the quality and relevance of the research produced over the 15-year life cycle of the Chair. We regularly interact and collaborate with many of our previous postdoctoral researchers who are now in academia,” she adds.

Research for the future

Viljoen-Bloom notes that, since the end of the Chair’s life cycle, many new ideas have flowed from the central theme of substrate-to-product via enzymes. One is that of using microbial hydrolases (enzymes that use water to break a chemical bond) to degrade bioplastics. The research group exploring the merits of this idea is being led by PhD candidate Wessel Myburgh. Through means of various studies, other team members under the co-supervision of Dr Rose Cripwell of SU’s Department of Microbiology are working on the recombinant expression of antimicrobial peptides in yeast to potentially serve as a partial replacement for antibiotics.

“One of the problems encountered during starch-to-ethanol fermentation is bacterial contamination. These bacteria could produce lactic acid that would cause the pH to drop and the whole fermentation process to stop. We have now developed industrial yeast strains that express antimicrobial peptides effective against lactic acid bacteria and pathogenic bacteria such as Listeria monocytogenes, a major contributor to food-borne listeriosis,” Viljoen-Bloom explains.

Snapshot of the Chair’s achievements (2007 to 2022)

286

book chapters and research papers in accredited journals

19

papers on average per year

16

patents

190

postgraduate students and postdoctoral fellows supervised

44%

of postgraduate students and 52% of postdoctoral fellows were female

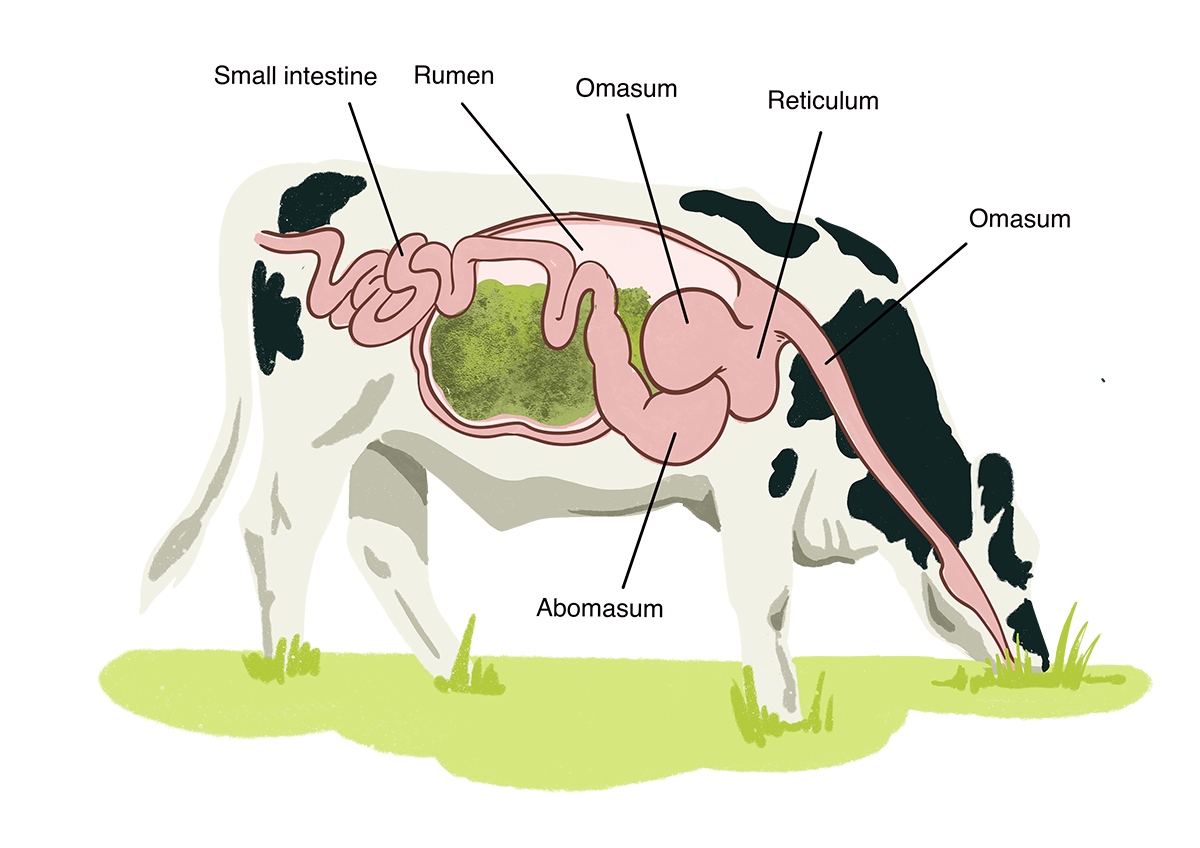

The ruminant digestive system

Cows provide ideas on what to do with agricultural waste

When Dr Sesethu Njokweni dreams big, he sees himself owning a cattle farm where the tractors are fuelled by the very cows that he keeps — specifically by their rumen, or cud.

He hopes that his own research, which builds on that of others around the world, will help to make this dream a reality.

Njokweni, currently a postdoctoral fellow in SU’s Department of Microbiology, obtained his PhD from SU in 2021 as part of the research efforts of the SARCHI Chair in Biofuels and Other Alternative Clean Fuels. He has worked on biofuels-related concepts since joining SU and the Chair’s activities in 2016 as an honours student.

“I come from a rural area in the Eastern Cape and have always been interested in farming. When an animal-related project came by, I seized the opportunity,” he says.

His work is inspired by cows’ ability to digest tough plant material — thanks to the microbes in their four stomachs and intestines — and turn it into precursors to milk.

Mammalian ruminants have naturally evolved to perform anaerobic digestion of plant material, Njokweni and his co-authors point out in a review article in the journal Catalysis. The paper introduces the idea of using the rumen microbiome to improve anaerobic digestion processes.

He hopes his ideas will improve upon current such processes that use a mixture of microbial cultures to break down organic waste material (such as fruit pulp, sugarcane bagasse, and invasive plant matter) and then convert it into biogas.

On grounds of his studies, Njokweni knows that if the final part of the biogas production process is suppressed, it is possible to produce industrial-grade organic acids such as acetic, propionic, butyric, valeric, and caproic acids.

While constituting a way to create bioenergy and high-value “green” chemicals, this process could also provide a solution to the growing problem of how to tackle agricultural and other types of organic waste. In South Africa alone, around 5,35 million metric tonnes of sugarcane bagasse and 1,2 billion tonnes of fruit waste are produced yearly, while up to 11,30 million metric tonnes of invasive plants are removed.

Njokweni’s doctoral research focused on establishing a carboxylate platform that uses certain microbes found in rumen to convert agricultural waste into volatile fatty acids. This work holds promise for the conversion of fruit pomace and invasive plants, notably the mesquite tree (Prosopis juliflora). The journal Bioresource Technology published an article on the latter work, co-authored by Prof Paul Weimer of the University of Wisconsin in the US, as well as SU microbiologists Dr Marelize Botes and Prof Emile van Zyl.

During his studies, Njokweni also developed preservation techniques that enable the long-term, repetitive use of core ruminal microbiota for volatile fatty acid production. He also analysed the population dynamics of the preserved core ruminal microbiome to determine shifts that may have occurred relative to fresh rumen.

If South Africa is to be powered through bioenergy, Njokweni believes this rumen-based biogas should be an option to consider alongside solar and wind power. He’d like to see small-scale bioreactors on rural farms and even wildlife ranches generate extra income for their owners through the production of volatile fatty acids and biogas.

To this end, Njokweni has already determined how to make the smooth long-term running of such bioreactors possible: by adding rumen frozen in glycerine to a bioreactor to ensure its constant optimal functioning. (He found that frozen rumen works even better than fresh rumen.)

He is now investigating whether there is value in using the fibre-rich rumen fluid or faecal matter from wild ruminants such as giraffes as inocula for volatile fatty acid production. So far, it is proving to work even better, as noted in a paper he is currently working on as lead author.

The research initiatives reported on above are geared towards addressing the United Nations’ Sustainable Development Goals numbers 3, 6, 7, and 15, and goals number 1, 5, and 7 of the African Union’s Agenda 2063.

Useful links

Senior Chair of Energy Research (CoER): Biofuels and Other Alternative Clean Fuels

SU’s Department of Chemical Engineering

SU’s Department of Microbiology

Research reveals environmental and commercial benefits to tackling bioplastics disposal dilemma

What can waste disposal learn from cows?

Demo waste plant set to improve the sustainability of SA’s paper industry

X: @MatiesResearch and @StellenboschUni